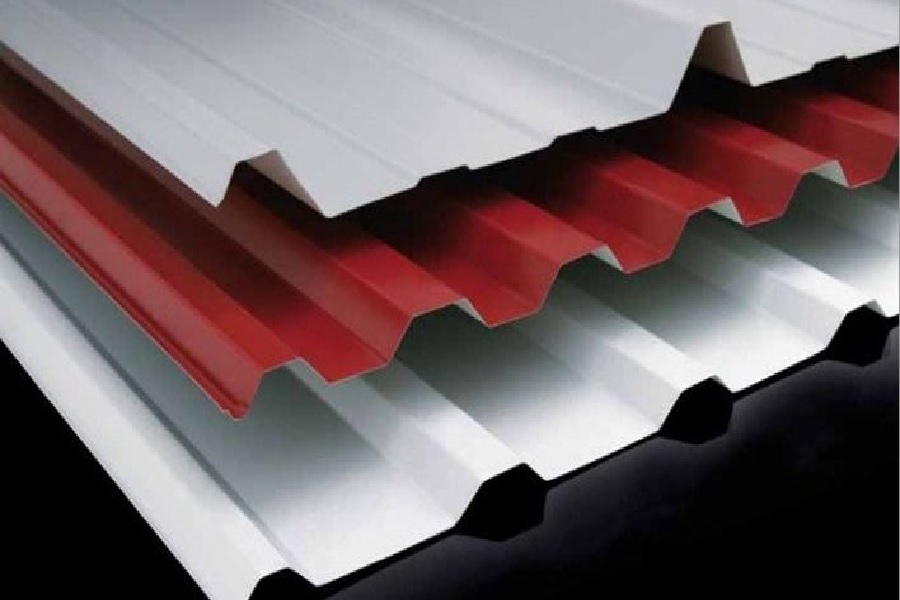

polymer sheets; Functional materials with multiple uses

It is very common to use polymer materials in various industries due to their properties and many applications. These materials are used in making all kinds of polymer sheets, polymer concrete, use in polar solvents, food industry, alkaline and acid environments, tank linings, packing steel coils, etc. With high resistance to chemical factors and affordable cost, polymer sheets are used as a group of the most widely used materials in various industries. Based on this, in this article from the Tehran Plimer Sharq website, we are going to do a complete review of polymer sheets.

What is polymer sheet?

Polymer sheet is a kind of durable and functional coating with extremely low permeability, which is used to pass all kinds of fluids. This type of sheet consists of a large number of interconnected sheets, which after being impregnated with materials such as: Elastomer, geotextile and polymer sprays are made into polymer sheets. Also, in the production of raw materials for polymer sheets, the raw materials include: There are polyester resin, plasticizers, carbon black, antioxidants, lubricants, and carbon black. In polymer engineering, extrusion and calendering processes are used to process these sheets.

Advantages of using polymer sheets in industries

All kinds of polymer sheets are resistant insulation for storing and conducting fluids, which, due to their chemical compounds, have a high resistance to tearing, decomposition, and ultraviolet (UV) rays. Also, having a low coefficient of thermal expansion, high flexibility and resistance to perforation, the use of these sheets in environments close to water or acidic environments has become common. Of course, do not forget that the applications of polymers are not only limited to the production of sheets; They can also be used to produce materials such as air-dried polymer paste.

Accordingly, the most important advantages of polymer sheets are:

- Resistant chemical coating to prevent surface corrosion in corrosive fluid ponds and tanks

- Possessing antistatic properties and preventing sparks and trapping electricity

- The possibility of ordering sheets according to needs in different thicknesses and sizes

- Preventing rapid ignition due to the property of fire block

- Transparent, semi-transparent and non-transparent production based on customer needs

- Having suitable thermal resistance and high pressure tolerance against water

- Using all kinds of sheets with different thickness and good quality

- The neutrality of the sheets against additives and pollution

- High resistance to being chewed by animals

- High resistance in dry and wet environments

- Ease of making large sheets

- Excellent resistance to cracking

- Having a useful life of 40 years

- Free of any toxins and harmful substances

- Resistance to earthquake waves

- Very high permeability

- Eco-friendly

- Simple replacement and repair

The process of making and processing polymer sheets

Polymer sheets go through a complex and specialized manufacturing process to reach the production stage. These sheets are put together using polyethylene welding or using other specialized methods, and in their structure, polymers such as: Polyvinyl chloride and polyethylene are used.

In general, for the production of polyethylene polymer sheets, HDPE polyethylene is used, which should be easily cut. Also, due to the thermo-softness of these sheets, the polymerization process must also be carried out in their production.

In the process of making and processing polymer sheets, first, criteria such as: Melt flow index, molecular weight, crystallinity and density are evaluated. Then the extrusion process is used to produce sheets. In this process, the white or colored granule goes through the melting and extrusion process, and after changing its shape, it becomes a sheet and is cut in thicknesses of 3 mm (poly 3) to 200 mm.

On the other hand, after melting in the tank of the sheet-making machine, the petrochemical granule turns into a liquid and maintains its liquid state by being exposed to high pressure and temperature. When the degree of fluidity reaches the desired level, this material is removed from the ejector of the device (head) and the product is produced, and after the product is in the form of warm paste sheets, the thickness and width of the sheet are applied according to the customer’s order.

polymer sheet; A resistant material with various applications

Due to its unique features and various advantages, the use of polymer sheets is increasing day by day. For this reason, many industries such as: Road construction and agriculture, automotive, plastic and paper material manufacturers, construction projects, etc. can benefit from the benefits of purchasing polymer sheets for various applications.

Some of the most important applications of polymer sheets are:

- Making a workbench

- Manufacture of pharmaceutical and laboratory equipment

- Design and implementation of flooring and ceiling

- window protector

- Sealing and covering the building

- Packaging Industry

- Construction of irrigation equipment

- manufacturing car parts

- Leaching ponds

In general, the installation of polymer sheets is very quick and easy and does not require expertise. Also, according to the quality of the sheets and the thickness of the production, these types of sheets are more affordable than the expensive stone and concrete coverings. Accordingly, in the following, we will discuss the most important applications of various types of polymer sheets.

Construction of agricultural ponds

One of the most common applications of polymer sheets is the construction of agricultural pools. According to the properties of polymer pool sheets, these sheets are usually used in earthen pools, which have more applications than concrete pools. The important advantage of using this material for the production of agricultural pools is the lower price of polymer pool sheets compared to concrete structures. Heavy polymer or HDPE sheets are used in the construction and implementation of this type of industrial pools.

Accordingly, the most important advantages of using polymer sheets in agricultural pools are:

- Very long life

- Sufficient resistance to sunlight and temperature rise and fall

- Having suitable resistance to concrete

- Having thermal resistance between +80 and -70 degrees Celsius

- 100% impermeability against materials compared to concrete and stone materials

The role of polymer sheets in the implementation of aquaculture ponds

Another type of polymer sheets used in the construction of industrial pools are geomembrane polymer sheets, which are used for the construction of aquariums. Due to their complete impermeability, these sheets are used as thermal insulation in the construction of aquatic pools.

Due to the neutrality of the polymer sheet and its non-combination with other materials, many entrepreneurs of the agricultural industry use this material to build all kinds of fish and shrimp breeding ponds. In the composition of polymer sheets, there are biological materials and polyethylene, which are the best option for the implementation and installation of the aquarium breeding pond due to the lack of adhesion with other materials.

Isolation of roof gardens

In addition to industrial applications, it is also very common to use geomembrane polymer sheets to insulate roof gardens. Polymer insulation, along with the basic drainage system, gives you the possibility of using an excellent insulation material with light weight, longevity and very high resistance.

Insulation of tunnels with the help of polymer sheets

Many industrial projects use geomembrane polymer sheets to isolate structures such as tunnels. This material is a suitable alternative to concrete due to its high flexibility in corners and inaccessible points and faster installation. Among the types of polymer sheets, heavy sheets or HDPE are the best options for tunnel insulation. Also, the use of VLDPE sheets is very important for insulating and sealing tunnels and preventing water infiltration and destruction of the structure.

Types of polymer sheets

The high variety of applications is due to the different characteristics and compounds used in all types of polymer sheets. According to the type of material used in the production of polymer products and production products, polymer sheets are divided into five different categories, each of which has different advantages.

Accordingly, the types of polymer sheets are:

- Polyethylene sheet (PE)

- Polypropylene (PP) plastic sheet

- Polycarbonate (PC) sheet

- Polyvinyl chloride (PVC) sheet

- Polytetrafluoroethylene (PTFE) sheet

polyethylene sheet; The best type of polymer sheets in the packaging industry

Polyethylene-based polymer sheets are a combination of polyethylene resin, masterbatch and antioxidants. This type of sheet is used as practical materials in the packaging industry, making car parts, making irrigation equipment and pipes, foundation isolation, roof gardens, tunnels and water storage pools in the agricultural industry. Polyethylene sheets are divided into LLDP, MDPE and HDPE based on heavy, medium and light types.

The applications of light (LLDP) or heavy (HDPE) polymer sheets are different from each other and based on their flexibility and thickness, they are used for insulation and dust cover applications. Heavy sheets are also used for sealing agricultural water tanks and aquatic pools. The table below provides you with complete information about the characteristics of polyethylene-based polymer sheets.

| Feature type | Description |

| Resistance to moisture and chemicals | Having the highest level of resistance |

| Weight | Light weight and can be used for the production of automotive products |

| Flexibility and cutting ability | Having suitable flexibility for cutting and shaping |

| Abrasion resistance | Having very high stability against abrasion |

| Impact resistance | High resistance at low temperature due to good elasticity |

| Electrical insulation | Complete non-conductivity against electric current |

| Material quality | Using first-class materials for the bright color of the sheets |

| Hardship | Medium hardness so that the sheets are easily cut |

| Resistance to water flow | Complete impermeability |

| coloring | Available in transparent and colored form |

Polypropylene (PP) plastic sheet

Plastic polymer sheets or thermoplastics with crystalline properties are placed between light polyethylene (LD) and heavy polyethylene (HD). While these products have good resistance and toughness, they also have good flexibility. The following table provides you with more complete information about polypropylene (PP) plastic sheet.

| Feature type | Description |

| Chemical resistance | Good stability against acids, bases and solvents |

| thermal resistance | Temperature up to 100 degrees Celsius |

| mechanical strength | Having suitable strength for the production of construction products |

The unique characteristics of polypropylene plastic sheet make it a versatile material in various industries. These sheets are divided into different categories according to their applications. Among the types of polymer sheets, these types of products, such as polyurethane or polyurethane sheets, have more applications and uses than others. In the table below, we have stated the types of applications of plastic polymer sheets.

| Type of PP polymer sheets | Property | applications |

| PE plastic sheet | LLDPE and LDPE light polyethylene | Manufacturing of industrial parts, medical prostheses, stainless steel banks, light separations and packaging of steel coils. |

| ABS plastic sheet | Glossy appearance | Refrigerator door frame and internal cabinet |

| PET plastic sheet | Production in two types of bottles and fibers | Production of bottles, clothes and all kinds of PET films |

| Hips plastic sheet or polystyrene | High strength, suitable molding, possibility of reprocessing, maintaining stability of dimensions and temperature, printability, adhesion and colorability. | Use in electrical industries, construction compounds and general goods |

| GPPS plastic sheet or crystal | Unparalleled transparency, having a low crystallinity percentage, production in transparent, icy, cool and galashi form. | Application of crystal polymer sheets in different industries |

| Clipped sheet | Having high chemical resistance and increasing the lifespan of concrete structures | Protecting the structure by preventing sewage infiltration and protecting underground water from pollution caused by sewage leakage |

Polycarbonate (PC) sheet

Another one of the most practical types of polymer sheets is polycarbonate sheet, which is used in various industries due to its special features. Due to the high transparency of polycarbonate, manufacturers of glass structures use polycarbonate plastic products for welding thin sheets of facades of buildings and windows.

Among the most important applications of this type of polymer sheets are: A suitable replacement for glass in construction applications, the production of resistant shields, auto parts, safety glasses, automotive and aerospace industry, and protective material against the harmful rays of the sun. To know the characteristics and applications of polycarbonate sheet, pay attention to the table below.

| Feature type | Description |

| transparency | High transparency |

| Impact resistance | It is about 200 times more resistant than glass |

| Weight | Lower weight than glass |

| UV resistance | Having the right resistance |

Polyvinyl chloride (PVC) sheet

Most people have heard the name of PVC polymer sheets. Usually, female PVC is produced in white color; But polyvinyl chloride coatings are produced in two types, glossy and matte, with different thicknesses and sizes. These sheets are highly popular among buyers due to their waterproof and anti-scratch properties.

Also, the flexibility of this type of sheet is between light geomembrane and heavy geomembrane and its most applications are in industries and mines. Among the most important applications of polyvinyl chloride sheet are: She pointed out the manufacture of drainage pipes, the transportation of chemicals, the production of electric cables, parts of electrical equipment and the production of plastic parts related to household appliances and construction industries.

The most important features of PVC polymer sheets are:

- High resistance: This material has high resistance to chemicals and ignition

- Insulation against electricity: Due to the high resistance of PVC against heat, this polymer sheet is used in the construction of many electrical equipments.

- Good flexibility: With excellent cutting ability, PVC sheets have good flexibility

Polytetrafluoroethylene (PTFE) sheet is the famous Teflon

The last category of polymer sheets are polytetrafluoroethylene or Teflon. These types of sheets have various applications due to their high chemical resistance, low friction coefficient, optimal thermal stability up to 260 degrees and very low adhesion. Among its most important applications, it should be mentioned the manufacture of mechanical and engineering parts, use in the chemical and medical industries, and the production of Teflon and non-stick containers.

Accordingly, the most important features of polytetrafluoroethylene sheet are:

- Good resistance in high and low temperature

- Stability in acidic and alkaline conditions

- abrasion resistance

- Good electrical insulation and anti-corrosion

- Anti-erosion

- Easy cutting and drilling

- Having proper tensile and impact stability

- Excellent flexibility and adaptability

- Light weight

What is the price of polymer sheets?

Due to the variety and countless applications of polymer sheets, it is not possible to consider the same price for buying these sheets. The price of these materials is in different ranges according to currency fluctuations, sheet type, thickness and size, partial or wholesale purchase and credit of the sales center. For example, for the purchase of Pars polymer sheets, the purchase price should be determined based on the conditions of the structure and the order capacity.

Buy the highest quality polymer sheets from Tehran Plimer Sharq

Choosing reliable sales centers to provide all kinds of polymer sheets helps to choose first-class products while reducing purchase costs. For this reason, many merchants and companies are looking for reliable collections of selling polymer sheets.

Tehran Plimer Shargh Company is one of the best groups in the field of preparation, distribution and production of polymer sheets, polymer raw materials, compounds, plastic injection, polymer granules, vacuum forming and color masterbatch. Our collection offers you a variety of services by offering competitive prices, guaranteeing the quality of goods, variety of raw materials and daily support. You can contact the experts to buy polymer sheet and other products of Tehran Plimer Sharq Company through our website or call 02177792662.

No comments