What is a compound?

Compound is a combination of polymer materials such as various grades of polyethylene and such, which is added to raw materials in order to increase physical, mechanical and thermal properties. These compounds are generally produced in the form of granules and used in the composition of various polymer products. In other words, the compound includes a mixture of several types of polymer bases with additives to improve the structure and properties of the manufactured product.

Why do we use compounds?

Sometimes, when producing some polymer products, manufacturers face problems such as weak physical properties, reduced properties, undesirable color, etc. As a result, the masterbatch cannot be used due to product incompatibility. In these cases, by adding materials such as compounds during the plastic injection and extrusion process, the chemical properties and reactivity of the product are strengthened. From the economic and health point of view, the use of compounds in the production of polymer products is more economical than masterbatch types. Because the compound does not have the side costs of cleaning and compounds in using the masterbatch.

Structural characteristic of polymer compound

The polymer compound consists of three main components in its structure, which are used to increase the properties of the product. These three components include polymer base, compatibilizing agent and other additives. Therefore, the compound must be added to the product that also has a polymer base so that it can be more easily integrated with it. The task of the second component is to create compatibility between the compound and the product so that it can be uniformly mixed with the product. Otherwise, the compound will not spread uniformly and continuously in polymer materials. The third component of the compound improves the properties and characteristics of the final product, some of which also lead to a change in the color of the final piece.

The most famous types of compounds

In general, in many applications, we need to add other materials to polymer bases to obtain certain properties. Two types of the most common polymer compounds are polyethylene polymer compound and propylene polymer compound. In fact, when we add additives to a polymer of polyethylene structure, the result is polyethylene polymer compound, and on the other hand, when additives are added to a polymer of propylene structure, the result is polypropylene compound. Different industries use polymer compounds depending on the desired applications in the production of their products. In many industries, it is possible to use both, but in general, due to the properties that polyethylenes have, they are mostly used in the packaging, automotive, etc. industries, and because of the properties that propylene has in industries such as Pipes, home appliances, etc. are mostly used.

Polyethylene compound

Polyethylene compound is one of the most important and practical types of compound, which is widely used in the production of polyethylene pipes for water supply. This type of compound consists of a series of industrial waste and other chemical materials, which has properties such as high resistance to direct sunlight and various mechanical impacts. The mentioned compound, while having an ideal quality, has a reasonable price; For this reason, it has the ability to compete with similar foreign markets. In the following, we will examine the most important grades of polyethylene compound.

- Low-density polyethylene (LDPE): This polyethylene has low tensile strength, and its other characteristics include flexibility and the possibility of decomposition by microorganisms.

- Heavy High Density Polyethylene (HDPE): This polyethylene has higher tensile strength than other polyethylenes.

- Medium density polyethylene (MDPE): It is a special type of polyethylene that is between heavy polyethylene and light polyethylene in terms of polymer structure and density. Most medium density polyethylenes have a linear structure and have special applications such as the production of large tanks for water storage, etc.

- Linear light polyethylene (LLDPE): Linear light polyethylene is obtained by adding normal butene comonomer to ethylene during the polymerization process. Linear light polyethylene has superior mechanical properties compared to light polyethylene, for example, by adding it to light polyethylene, polymer films with higher strength and tensile strength can be produced.

- Ultra high molecular weight polyethylene (UHMWPE): Polyethylene with a molecular weight between 3 and 6 million is called ultra high molecular weight polyethylene or UHMWPE. Polyethylene with a very high molecular mass is used in other cases such as making resistant pipes in the oil and gas industry, waste discharge pipes, etc.

Polypropylene compound

Polypropylene compound is another type of compound used in the production of polymer products that have a composite structure. After polyethylene, this compound is one of the most widely used types of compounds. This type of compound is used in the manufacture of car parts, the production of household appliances and plastic items used in kitchens, and the preparation of pipes and fittings.

Compound reinforced by glass fibers

These compounds have high mechanical and thermal properties. This type of compound is widely used in various automotive, household appliance, electrical and electronic industries. This type of compound is mostly used in products that are covering and insulating.

Engineering polymer compound

Engineering compounds are used in the manufacture of engineering polymer products with special design and suitable for specific usage conditions. This compound is used to increase mechanical strength, resistance to all types of abrasion, chemical acids and bases. Polymer products produced by plastic injection and extrusion methods, by adding engineering compounds, have a longer lifespan. Engineering compound production centers produce these compounds according to the customer’s and user’s needs.

Rheological cleaning compounds

Due to their rheological properties, these compounds are used in the cleaning operations of cylinders, mandrels and dies in extruders. The mentioned compound is used in the production devices of polymer products such as polyethylene films, sheets, tubes and cardboard plastics. The cleaning compound has the ability to remove any impurities and discoloration in the shortest possible time. In the extrusion process using a cleaning compound, the amount of waste produced is very low, which is a positive point about rheological compounds.

Filling compounds

The filler compound is produced based on different percentages of filler and according to different polymer bases. The type of structural formula used in this type of compound, besides creating excellent properties in the polymer compound, also reduces the final price of the product. The mentioned compound is used in extrusion, plastic injection and thermoforming processes.

Sound insulation compound

Sound insulation compound with a high percentage of barium sulfate is produced on the basis of polypropylene polymer. This compound is used in sewage pipes as well as building structures and buildings that need sound insulation. In general, acoustic compound is used in products that are used for insulation.

Differences between polyethylene and polypropylene compounds

As we saw in the previous section, the two most common types of polymer compounds are polyethylene and polypropylene compounds. In this section, we want to point out the differences between these two types. In the following, we point out the main differences between them.

- Polypropylene is easier to produce than polyethylene.

- Polypropylene is more rigid than polyethylene.

- The chemical resistance of polypropylene against organic solvents, acids and electrolytes is higher than that of polyethylene.

- The resistance to cracking of polypropylene is high, but polyethylene has somewhat higher elasticity and flexibility.

- Polypropylene films are more printable than polyethylene.

- Polyethylene is a biocompatible polymer and its recycling is better than polypropylene.

Applications of polyethylene and polypropylene compounds

Polyethylene and propylene compounds have many variations and are used in different industries to produce different products. In the following, we will mention the products in which polyethylene and polypropylene compounds are used.

Applications of polyethylene and polypropylene compounds in water supply and sewage pipes

Two of the most common types of water supply and sewage pipes are using polyethylene and polypropylene compounds. due to properties such as resistance to corrosion, resistance to decay, resistance to wear, ability to connect very firmly and flexibly, lightness, low costs, etc., from a variety of polyethylene compounds in black pipes that withstand pressure It requires high, it is used.

Using polyethylene in the construction industry

Also, due to properties such as resistance to corrosion, resistance to decay, resistance to hot and cold sewage, resistance to freezing and impact, low sedimentation, lightness, etc., of various propylene compounds in the production of white pipes or Green is used.

Applications of polyethylene and polypropylene compounds in packaging industries

At the same time, both types of polyethylene and propylene compounds are used in this industry, but due to properties such as less dirt absorption, durability against tearing, suitability for packing heavy items, etc., they are suitable for They do special packaging. In addition, properties of propylene compounds such as clearer crystal for better product presentation, suitability for food packaging, etc., have made this group a good option for use in some industries and products.

Applications of polyethylene and polypropylene compounds in wood-plastic flooring

Wood-plastic flooring is another product of the construction industry that uses polypropylene and polyethylene compounds. Polyethylenes have high abrasion and coating resistance, high impact resistance, and in contrast to polypropylene, they have high fatigue resistance, no cracking despite stress, and excellent chemical resistance, which makes them used in various products of this industry. Among the other uses of polyethylene and propylene compounds, we can refer to cases such as use in the automotive industry to manufacture various parts, use in the toy industry to produce all kinds of toys, use in the medical industry to produce all kinds of laboratory and medical equipment, etc. Due to their widespread use, we omitted to mention their details in this article.

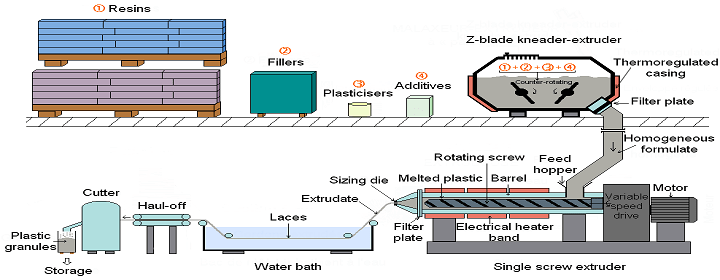

Compound production process

The polymer compound is produced during complex and long steps in the chemical industry. The first stage of its production is melting the raw materials of the plastic industry and its types, which is done by a machine called an extruder. In this way, first the powder mixture of basic polymers and additives enters the extruder and after melting, it comes out from the die located at the end of the machine. In the next step, the molten material is cooled and frozen during the cooling process and ready to be cut. At this stage, the compound is cut into the size of granular granules by the cutter. The compounds produced under special temperature conditions are stored in warehouses to check their quality and finally be supplied to the market of plastic products and other industries.

What is the difference between compound and masterbatch?

The type of molecular structure of polymer compound and masterbatch are somewhat similar to each other, and their difference is in the behavioral reaction, the percentage added to the final products, and their use in various manufacturing industries. That is, when there is no possibility of strong reaction between the masterbatch and polymer raw materials in plastic injection extruders and polymer film production, compounds are used. In fact, the compound is a polymer compound that is used in the production of plastic goods without any additional compounds. In contrast, masterbatches cannot be used alone in the production process and require the simultaneous use of polymer bases and other necessary additives.

Advantages of using compound over masterbatch

The important advantages that various types of polymer compounds have over masterbatches and have caused compounds to be used more than masterbatches in the production of polymer products; It includes the following:

- The convenience and ease of using compound methods is more than masterbatch.

- Toxicity and dangerousness have limited the continuous use of some types of Masterbatch.

- Sometimes it is not possible to obtain the required quality in the product by only using masterbatch in the production line, and it is necessary to use compounds.

- The hygiene and completeness of the compounds compared to the masterbatch makes the use of the compound more widely used in health production industries.

- In the use of masterbatch with injection and extruder systems, it is not possible to mix with polymer materials, but this is not the case with polymer compounds.

Application of polymer compound

Different types of polymer compounds are used in various manufacturing industries according to their properties and characteristics. Among their most important uses, the following can be mentioned:

- Application in water supply and high pressure pipe production devices

- Production of all kinds of inflatable films

- Application in automotive industry, such as the production of car bumpers

- Production of household appliances, tools and plastic toys

- Production of electrical and electronic components

- Making all kinds of disposable containers through the thermoforming process

- Application in making hoses, water and sewage pipes

In general, the production of polymer compounds is done according to the customer’s order and also the expectations she has from a compound product.

Advantages of using compounds

The use of some types of polymer compound increases the impact resistance in normal and negative temperatures. Other advantages of the compound include the following:

- Being affordable and creating competitive markets among all domestic and foreign producers

- Standard spread of soot evenly

- Increasing the product’s resistance to direct sunlight

- Increased strength and resistance in negative temperatures

- Use of high-quality polymer raw materials in product manufacturing

- Quality and quantity assurance in the sales market

Conclusion

Polymer compound is one of the types of widely used additives in polymer production industries. The production process of compound is done like other polymer products through extruder devices and extrusion process. Each type of polymer compound has different characteristics, properties and applications. The most important types of compounds include polyethylene and polypropylene compounds as fillers, rheological cleaners, reinforcement with glass fibers, engineering, etc., which are used in various industries. Among their applications, we can mention things such as making high-pressure water supply pipes, producing car parts and accessories, electrical appliances, and all kinds of disposable containers.

No comments