Engineering compounds are one of the most widely used additives to plastics. Any product that is made by human hands will be marketed with many weaknesses and strengths. Plastic products also have weaknesses that various additives can cover this weakness. Engineering compounds are used in most plastic products. The quality of plastic is improved with the help of engineering compounds and provides many features to the consumer. In this article, we are going to explain more about engineering compounds.

What are engineering compounds?

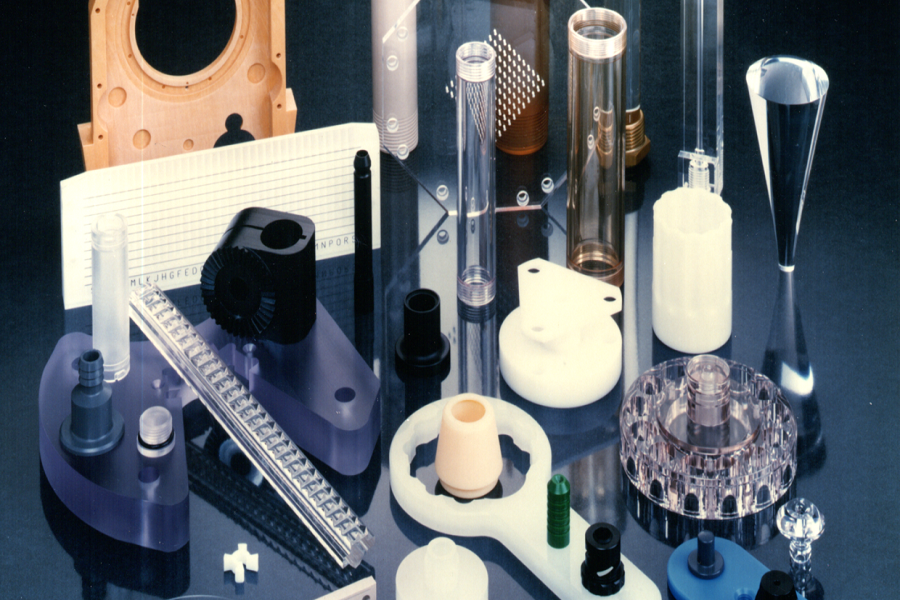

The plastic manufacturing industry is very complex and extensive. The production of plastic goods is done according to certain rules so that the consumer can use this product without any problems. Even the amount of ingredients and reinforcements are of special importance. Reducing or increasing these compatibilizers can change the final product and make a poor quality product. Polyethylene and polypropylene polymers are the basis of engineering compound production. The raw materials used to produce this type of compound can be new or recycled. Engineered compound is a type of plastic that is strengthened and created by adding materials such as fibers, glass, minerals, etc.

The compatibilizers in this compound help in the production process of plastic products to eliminate the defects of these products. Adding this compound to the production stage makes unique products with many features. With the help of engineering compounds, it is possible to produce plastics that are functional and suitable for the conditions. The amount of engineering compound is of particular importance in manufacturing products; Because it has a great impact on the produced product.

The efficiency and use of these types of products are superior to ordinary plastics and are highly popular among manufacturers. Engineering compound is used as a substitute for masterbatches, that is, if masterbatch cannot be used in extruders or plastic injection machines, engineering compound will be used. This plastic is produced at a more cost-effective cost and results in a lower cost for production.

Application of engineering compounds

In the engineering compound, mineral compounds are used, which will preserve the health of the environment. As you know, plastics are considered a great danger to the environment; But the engineering compound is the best choice for not harming the environment. Engineering compounds have many uses in different industries. The use of this type of compound is seen in abundance. In the following, we examine the applications of engineering compounds:

- automobile manufacturing: The automotive industry needs some kind of plastic to make reliable cars. These compounds are the best option for making plastic products with the help of engineering compounds.

- Pipes and fittings: Today, plastic pipes and fittings are a good alternative to iron pipes and fittings, and plastic pipes and fittings can be seen in most places. Pipes and fittings of the engineering compound type can transfer water flow easily and eliminate the disadvantages that iron causes for water.

- electrical devices: Electrical devices, including wire covers and frames of electrical devices, must be made of quality plastic in production. Engineering compound can be the best compound for making products in the electrical industry.

- Home Appliances: In addition to metal parts and wiring, household appliances need a body and parts to protect the device. This product should be light weight and excellent application, which is made by adding engineering compounds to the raw materials to create a unique product.

Advantages of engineering compounds

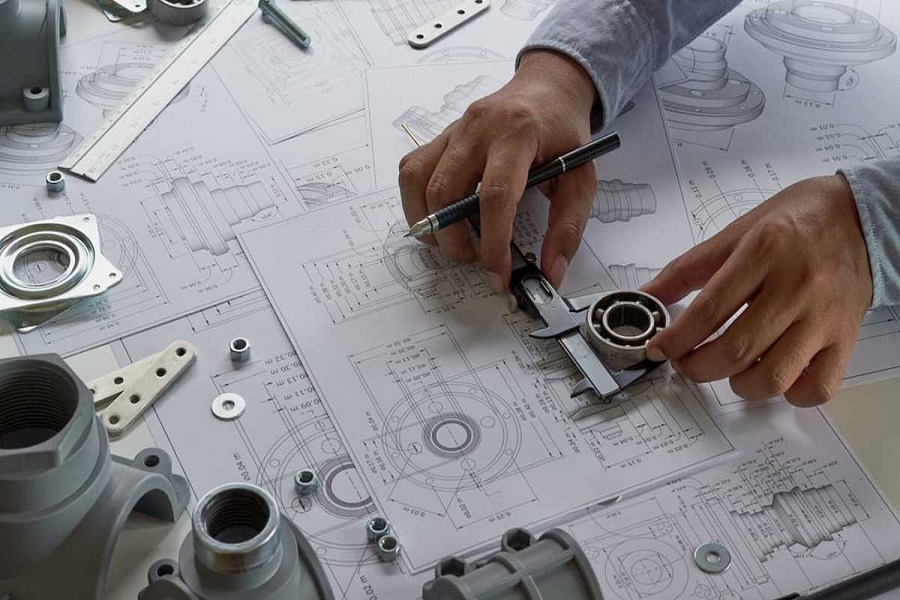

The engineering compounds that exist in the market come in different bases. Each of these compounds has special characteristics. The production of plastic products is associated with many challenges and problems. Adding an engineering compound to the plastic production base will minimize these problems and produce very high quality parts. These parts are made according to the conditions of use and how to use them. The properties that the compound imparts to the plastic make it an ideal product for various industries. These parts are used for various purposes. When engineering compounds are used in various industries, there are many benefits, which include:

- Resistance to heat increases.

- The tensile strength increases.

- Abrasion and scratches in products are minimized.

- It is more resistant to chemical reactions caused by contact with chemical solutions.

- Dimensions will remain unchanged.

- Flexibility and malleability are maintained with the help of engineering compounds.

- They have a longer lifespan than ordinary plastic products.

- The speed of production of products decreases.

Types of engineering compounds

Engineering compounds are known as a subset of polymer compounds. This type of polymers can be used in the absence of masterbatches. When the existing conditions do not allow the combination of masterbatch with polymer, engineering compounds are used; As a result, it improves the quality and properties of the product. The production cost is also reduced despite the addition of the engineering compound and will result in a cost-effective production process. These types of plastics are sold in different types that are combined according to the conditions of use. Each of these compounds with different characteristics are placed in the production program. In the following, we examine the types of engineering compounds:

- Polyethylene engineering compounds

- Polyethylene engineering compounds

- Polyethylene engineering compounds

final word

Engineered compound is in the category of plastics and by producing plastic products with compound, quality goods are made. In the last decade, the use of plastic as consumer goods has been the most used. Wherever you go, you will see a corner of the plastic industry. As mentioned, engineering compounds are planned in different applications. Adding reinforced compounds to the raw materials made suitable plastic products available in the market.

These types of compounds have many engineering applications that make high-quality parts according to production conditions. Engineering compound creates better conditions for production. Consumers who use compound goods are more satisfied. To determine the correct amount of engineering compound, you should get help from an expert. In this way, you have the best choice in the production of goods. In this article, we have provided complete information about Kapand Engineering in order to help in the production of products.

No comments